How a leading European Automotive Radar manufacturer achieved Automated Inspections, reduction in Production delays and Return rates

Business Impact

Executive Summary

- Client needed to mitigate manual inspection methods (with inherent missing issues), production delays and high return rates.

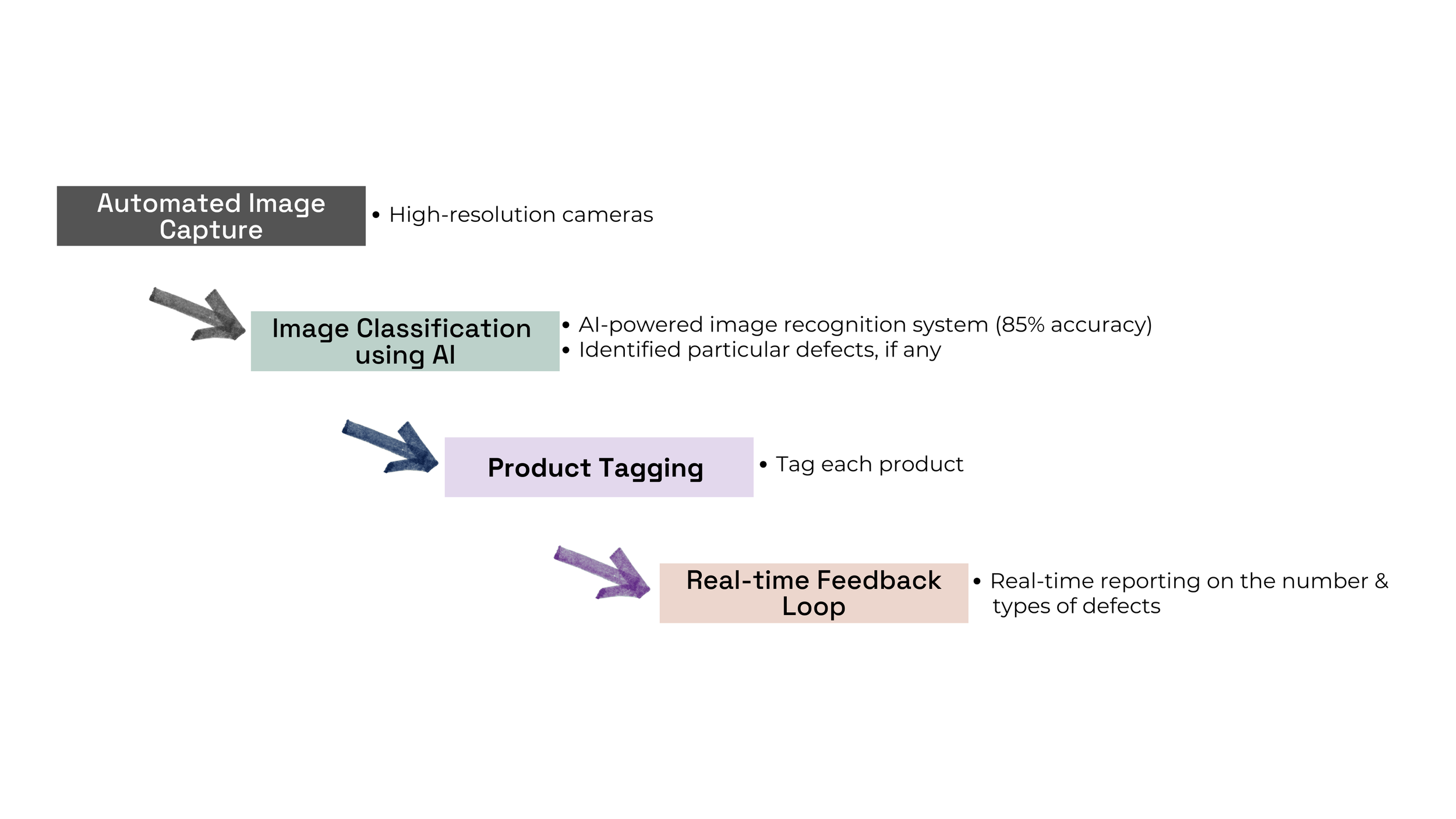

- By deploying Automated Image Capture tech (through High-resolution cameras), Image Classification through AI-powered image recognition systems, product tagging & real-time feedback loop, real-time reporting on the number & types of defects was targeted.

- The new automated-system reduced inspection time by 90% and product returns by 70%.

Read the Story…

In today’s high-stakes manufacturing world, companies face relentless pressure to deliver flawless products at speed and low cost. For one client, this meant battling missed defects from manual inspections, cascading production delays, and rising return rates that threatened both profits and reputation.

Their shift from manual inspection to AI-powered precision was more than a technology upgrade—it was a complete transformation of quality control and operations. This case study explores how automated visual inspection delivered major gains in accuracy, speed, and customer trust.

The Challenge: When Human Limitations Become Business Liabilities

The client, a mid-sized manufacturer in automotive and electronics, relied on manual inspections. But growing product complexity exposed critical weaknesses:

Human Error: Inspectors missed 15–20% of defects, despite skill and training.

Fatigue & Inconsistency: Repetition led to oversight and variation across shifts.

Throughput Bottlenecks: Manual checks slowed production.

False Choice: During peaks, speed often came at the expense of quality.

The result: 3–5% return rates, millions in losses, damaged customer trust, and costly scalability challenges.

The Solution: Deploying Next-Generation Automated Visual Inspection

Recognising that incremental improvements to manual processes would never deliver the transformation they needed, our client committed to a comprehensive overhaul of their quality control infrastructure. The solution centered on an integrated ecosystem of cutting-edge technologies designed to eliminate human subjectivity while dramatically increasing inspection speed and accuracy.

Advanced High-Resolution Camera Systems:

Precision Instruments: Installation of advanced cameras capable of capturing microscopic details invisible to the human eye, operating at speeds matching the fastest production lines

Multi-Angle Coverage: Each inspection station featured multiple cameras positioned to capture comprehensive views of every product from different angles

Specialised Lighting: LED lighting systems calibrated to highlight specific defect types—surface irregularities, dimensional variations, colour inconsistencies, and structural flaws

Real-time Processing: Integration with high-performance edge computing platforms capable of processing images in real-time without production delays

AI-Powered Image Recognition Platform:

Custom Development: A sophisticated platform built on advanced machine learning algorithms trained specifically for the client's product portfolio—not a generic off-the-shelf solution

Deep Learning Models: Convolutional neural networks (CNNs) trained on thousands of images representing both acceptable products and various defect types

Superior Detection: Models capable of identifying patterns and anomalies far beyond human visual capabilities, detecting subtle variations in texture, colour, dimensions, and structural integrity

Adaptive Learning: Continuous learning capability allowing models to be retrained and updated without disrupting production operations

Comprehensive Product Tagging and Traceability:

Digital Identification: Every product received a unique digital identifier tracking its journey through the quality control process

Dual Tagging System: Products tagged with both RFID chips and QR codes, enabling seamless tracking throughout manufacturing

Complete Traceability: Full tracking capability from raw materials through final inspection and shipping

Digital Quality Certificates: Each product passing inspection received detailed documentation of inspection process, detected parameters, and quality scores

Continuous Feedback Loop and Process Optimisation:

Real-time Adjustments: System could automatically adjust manufacturing parameters when specific defect types were detected

Predictive Analytics: Advanced algorithms analysed defect patterns and trends to predict potential quality issues before they occurred

Proactive Prevention: Enabling proactive adjustments to manufacturing processes, preventing defects rather than simply detecting them

MES Integration: Full integration with manufacturing execution systems creating seamless information flow between quality control and production management

Implementation and Results: Quantifying Transformation

The implementation followed a carefully planned three-phase approach designed to minimise disruption while maximising learning and optimisation opportunities.

Implementation Journey:

Phase 1 - Pilot Program (8 weeks): Focused pilot on single production line with highest-volume product, allowing thorough testing without disrupting overall operations

Phase 2 - Full Deployment (12 weeks): Modular rollout across all production lines with individual upgrades following planned schedule

Phase 3 - Optimisation (Ongoing): Continuous refinement, performance monitoring, and capability expansion based on production data and feedback

Training and Change Management: Comprehensive programs covering technical operation, quality processes, and helping staff understand technology enhancement rather than replacement

Dramatic Performance Improvements:

90% Reduction in Inspection Time: What previously required 2-3 minutes of manual examination was completed in 10-15 seconds by the automated system

Continuous 24/7 Operation: Unlike human inspectors, automated system operated without breaks, shift changes, or fatigue-related performance degradation

99.7% Detection Accuracy: Far exceeding the 80-85% accuracy typical of manual inspection processes

70% Reduction in Product Returns: Dramatic improvement in detection accuracy directly translated to fewer defective products reaching customers

25-30% Production Output Increase: Elimination of inspection bottlenecks allowed production lines to operate at optimal speeds

Quality Consistency: Every product evaluated using exactly same criteria, eliminating variations between different inspectors or shifts

Resource Optimisation Benefits:

Personnel Redeployment: Quality control staff redirected to value-added activities like process improvement, root cause analysis, and preventive maintenance

Scalable Capacity: System could handle increased production volumes without proportional increases in quality control costs

Predictive Maintenance: Ability to detect subtle quality variations often provided early warning signs of equipment issues or process drift

Strategic Impact and Future Implications

The transformation went beyond operations:

Cultural Shift: Data-driven decision-making replaced subjective assessments.

Collaboration: Integration with MES systems improved coordination across production, engineering, and maintenance.

Market Positioning: Higher quality became a competitive differentiator, supporting premium pricing and new business.

Workforce Growth: Rather than job loss, employees gained new skills in data analysis and process optimisation.

Conclusion: A New Paradigm for Manufacturing Excellence

By embracing AI-powered visual inspection, the client didn’t just fix problems—they redefined excellence.

Quantifiable Transformation Results:

90% reduction in inspection time enabling continuous quality control without production bottlenecks

70% decrease in product returns strengthening customer relationships and reducing warranty costs

Significant increase in production output while maintaining unprecedented quality standards

99.7% defect detection accuracy far exceeding human inspection capabilities

These results proved that digital transformation isn’t just about tools—it’s about reimagining processes, culture, and capabilities. In an increasingly competitive global market, those who combine advanced technologies with continuous improvement will thrive.

This case stands as proof that the future of quality control is AI-driven, data-powered, and relentlessly focused on perfect products.

Share this Post

Read More Success Stories