How a Tyre Manufacturer achieved Energy Efficiency, Emissions Reduction and better Environmental compliance

Business Impact

Executive Summary

- Client needed to address high energy consumption issue resulting in inconsistent environmental compliance, and unstable production output.

- By deploying & integrating IoT Sensors, managed by AI-powered data processing & optimisation algorithms, realtime energy optimisation, predictive maintenance, and environmental monitoring was targeted.

- The new system resulted in 15% energy savings, 20% reduction in unplanned downtime and 10% reduction in carbon emissions.

Read the Story…

Rising energy consumption poses significant financial and environmental risks for industrial firms striving for both productivity and compliance. The client confronted precisely this challenge: persistent high energy usage led to fluctuating compliance with ecological standards and inconsistent production output. This case study unpacks how data-driven, technology-first approach delivered powerful results—cutting energy use, stabilising operations, and reducing the company’s carbon footprint.

The Challenge: Energy, Environment, and Output in Collision

For manufacturers, energy isn’t just an operating cost: it’s a balancing act between regulatory compliance, operational efficiency, and profitability. In this case, the client was grappling with:

Excessive, wasteful energy consumption inflating costs and complicating budgeting

Inconsistent environmental compliance, risking regulatory penalties and damaging brand reputation

Unstable production output due to unpredictable machine and facility performance

Manual data collection and reactive maintenance only exposed issues after the damage had been done. The client needed a way to control usage in real-time, predict problems before they caused disruption, and embed sustainability deep within their processes.

The Solution: IoT Sensors, AI Analytics, and Live Optimisation

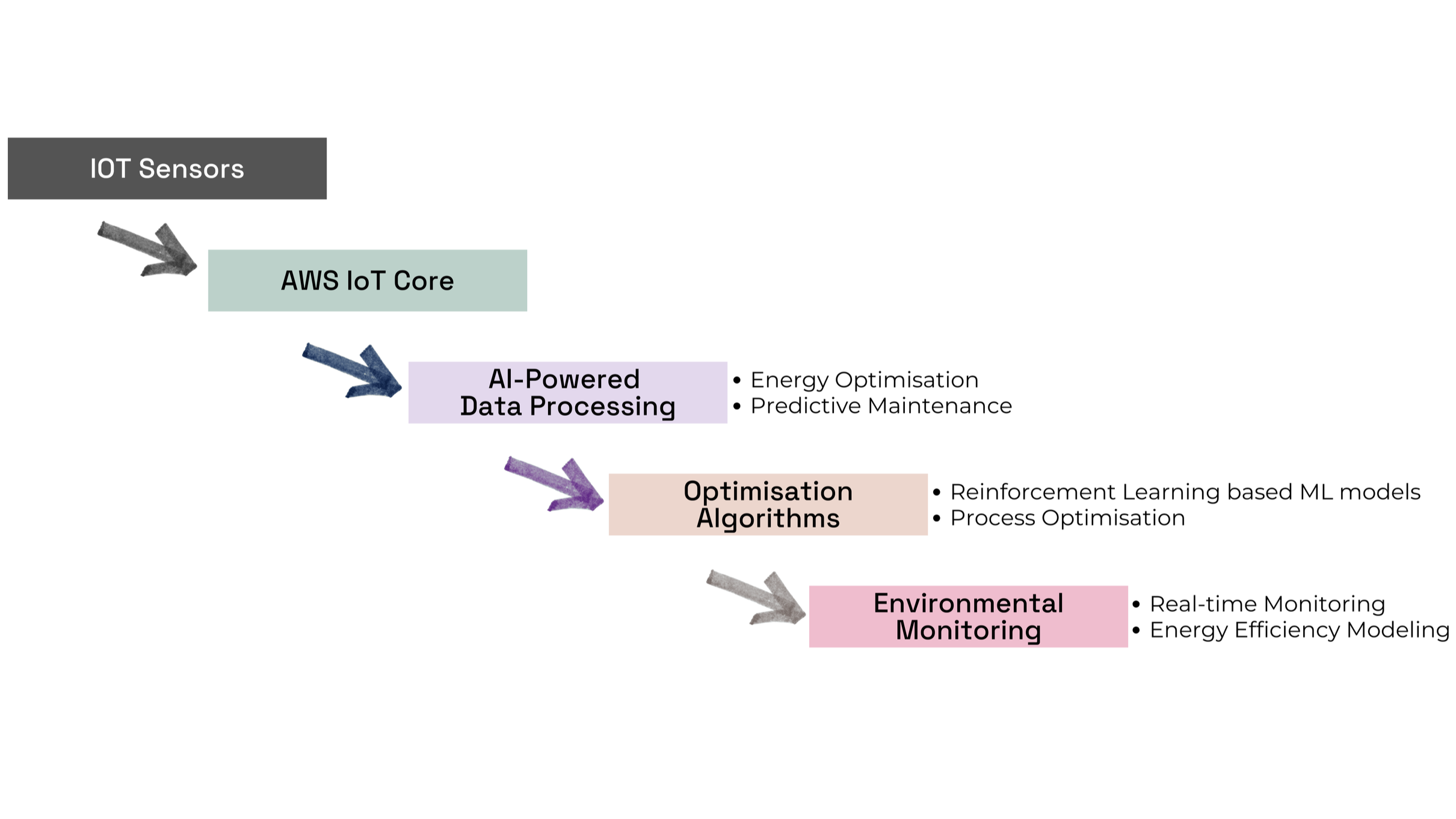

The path to transformation began with a network of IoT sensors—installed across energy-intensive equipment, production lines, and environmental monitoring points. These sensors streamed thousands of live data points every second, tracking electricity usage, emissions levels, temperature, operational status, and more.

At the heart of the new system were AI-powered data processing and optimisation algorithms. These tools sifted through the constant flow of sensor data, instantly spotting inefficiencies, forecasting spikes in consumption, and triggering both predictive maintenance scheduling and automated energy-saving actions.

Key abilities enabled included:

Real-time energy optimisation—Automated adjustments to machinery and HVAC in response to usage data

Predictive maintenance—Anticipating component wear and breakdowns to avoid costly unplanned downtime

Continuous environmental monitoring—Instant alerts if emissions or usage approached compliance thresholds

Now, facility managers saw actionable insights and risk warnings in a single dashboard, making it easy to optimise production and safeguard compliance—proactively rather than reactively.

The Results: Dramatic, Measurable Gains

It didn’t take long for these changes to produce powerful outcomes:

15% Energy Savings: Drastic cut in both costs and environmental footprint, thanks to real-time usage tracking and dynamic adjustment

20% Reduction in Unplanned Downtime: Predictive maintenance meant fewer breakdowns, steadier production, and better asset longevity

10% Reduction in Carbon Emissions: By closely monitoring and controlling output, the client consistently met (and often exceeded) regulatory requirements

Beyond the Metrics: Strategic and Cultural Benefits

While the headline numbers captured the scale of success, several deeper shifts occurred:

Sustainability as a Core Value: The client embedded environmental thinking into every production decision, gaining an edge in both compliance and corporate responsibility

Data-Driven Operations: Teams moved from guessing and reacting to planning and optimising, with live data always at their fingertips

Improved Reputation: Customers, partners, and regulators alike took notice as operations stabilised and reporting became more transparent

Conclusion

This case shows that deploying IoT and AI-powered optimisation is more than a technical upgrade—it’s a shift toward smarter, greener, and more resilient manufacturing. The client not only saved money and reduced emissions, but future-proofed their business in an increasingly complex regulatory and competitive environment.

If your organisation faces similar challenges, this story illustrates the transformative potential of intelligent technology—turning energy from a headache into a strategic asset.

Share this Post

Read More Success Stories