How a leading Consumer Brand achieved Inventory Optimisation and reduced Maintenance Downtime

Business Impact

Executive Summary

- Client needed to mitigate inaccurate inventory tracking, high maintenance delays & lack of realtime data.

- By deploying advanced Inventory management techniques, involving Tableau’s realtime reporting tools & use of QR codes & RFID tagging of equipment, realtime analytical reporting & predictive maintenance was introduced.

- The new system increased inventory accuracy by 95%, lowered maintenance delays by 60% and improved decision making by 25%.

Read the Story…

For organisations relying on the timely availability of equipment and materials, the impact of inaccurate inventory records and maintenance delays can be devastating. The client was experiencing these issues firsthand—inventory mismatches disrupted workflows, prolonged downtime raised costs, and decision-makers were left guessing without access to real-time data. This case study explores how a strategic transformation using automation, analytics, and live reporting delivered measurable gains in accuracy, efficiency, and business agility.

The Challenge: When Inventory Errors Become Business Risks

Imagine being unable to locate critical equipment right when it's needed, or finding that essential stock has run out unexpectedly. The client’s operations were hampered by such scenarios, all stemming from a reliance on manual inventory processes that were slow, error-prone, and incapable of supporting business growth. Maintenance teams faced frequent delays as they struggled to track asset history and upcoming service needs—a cycle that led to reactive repairs, lost productivity, and even customer dissatisfaction.

The core issue? A lack of real-time visibility. With inventory and maintenance data fragmented across spreadsheets, paper logs, and siloed systems, leaders could not make informed decisions, respond swiftly to new challenges, or proactively allocate resources. It was clear that a new approach was needed to break through these limitations.

The Solution: Bringing Data, Automation, and Predictive Insight Together

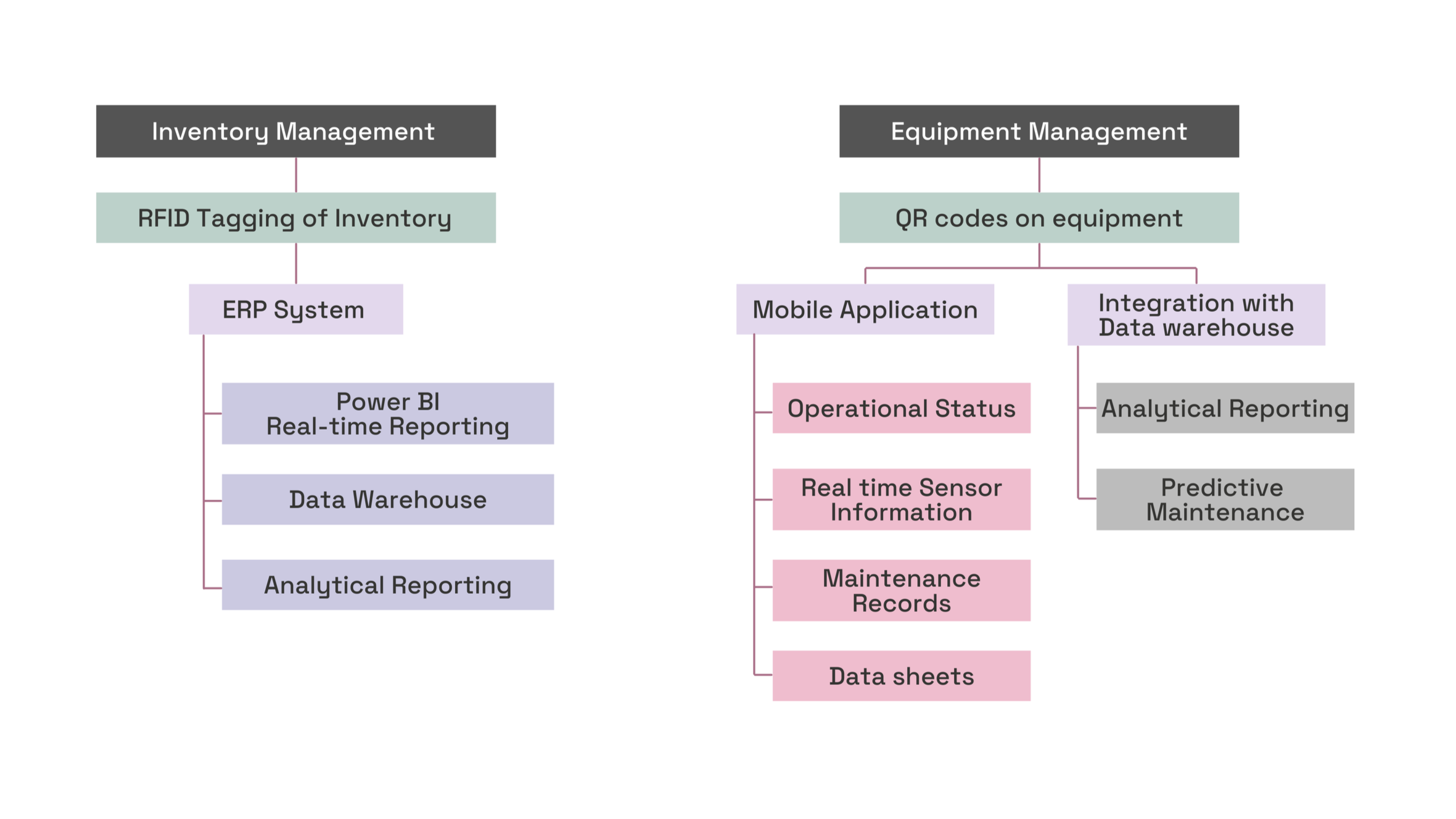

Step one was introducing Tableau as the backbone for analytics and reporting. Tableau connected data streams from every touchpoint within operations, updating dashboards in real-time and presenting a unified snapshot for teams at all levels. Suddenly, slow and error-prone batch reports were replaced with instant, actionable insight.

To eliminate manual tracking errors, QR codes and RFID tags were rolled out across all equipment and inventory items. QR codes enabled quick, foolproof scanning at every stage of movement, while RFID provided passive, real-time asset location updates. This technological leap ensured that every item was accounted for; automated status updates flowed directly into Tableau , making missing assets a thing of the past.

But this didn’t stop at tracking. Using historical data and live sensor feeds, predictive analytics for maintenance were layered into the new system. Now, potential equipment failures could be forecast before breakdowns occurred. Maintenance teams could plan repairs in advance, shrinking downtime, optimising schedules, and protecting business continuity.

The Results: From Reactive to Proactive—With the Numbers to Prove It

The impact of these changes was both immediate and profound:

95% Inventory Accuracy: The client’s inventory records became a precise, real-time reflection of reality. Stockouts and excess ordering dropped dramatically, with managers now able to trust the data when making purchasing and allocation decisions.

60% Reduction in Maintenance Delays: With predictive alerting and faster tracking, maintenance teams kept ahead of problems. Equipment operated at peak performance, and workflow interruptions were minimised.

25% Improvement in Decision Making: Access to real-time analytics empowered stakeholders to make timely, data-driven choices. This translated into smarter resource allocation, faster response to market changes, and improved overall strategy.

What Else Changed?

Beyond the headline statistics, our client enjoyed additional benefits:

Financial Savings: Fewer emergencies and overstock situations freed up budget.

Employee Morale: Teams felt more confident, less stressed, and better equipped to tackle problems.

Customer Service: Reliable processes meant faster delivery and higher satisfaction rates.

Why It Matters: Lessons Learned

This transformation demonstrates the power of integrating modern technology with analytics-driven decision making. Inventory management is not simply about counting stock—it’s about knowing the status of every item, predicting future needs, and giving teams the insight they need to act with confidence.

For any business struggling with similar symptoms—inventory inaccuracies, maintenance headaches, or slow data—this case stands as proof that a strategic shift towards automation and live analytics can result in nothing short of operational excellence.

Conclusion

The client's journey from manual headaches to technological empowerment is an inspiration for any organisation ready to modernise. By leveraging Tableau, QR/RFID technology, and predictive analytics, they unlocked new levels of accuracy, efficiency, and agility. Their story shows that with the right tools and the right approach, operational transformation is not only possible—it’s measurable, repeatable, and impactful for the entire business.

Share this Post

Read More Success Stories